Homogenizers

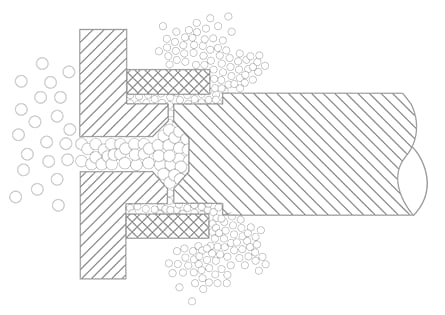

The method of operation of high-pressure homogenization

A pressurised product is subjected to turbulent and laminar forces in a very narrow ring-shaped gap.

In this process, fat globules or agglomerates are broken up and evenly distributed.

This physical energy input results in stability, colour intensity, flavour, consistency and a long shelf life, thereby reducing the use of stabilisers.

Machines for laboratory and pilot plant

Production machinery

Series HL2 – HL6

Standard series in robust design

- Maximal homogenization pressure: 700 bar

- Maximal 46,000 litres per hour (150 bar)

- Motor power: up to 250 kW

- High-performance, extremely robust and reliable crank drive

- Hygienic design, compliant with 3-A standards

- Pneumatic or hydraulic adjustment of the homogenizing valve

- Optionally available in aseptic design

- Excellent cleaning results in the CIP process thanks to high-quality surface finish and avoidance of dead spaces, compliant with EHEDG and 3-A standards

Production machinery

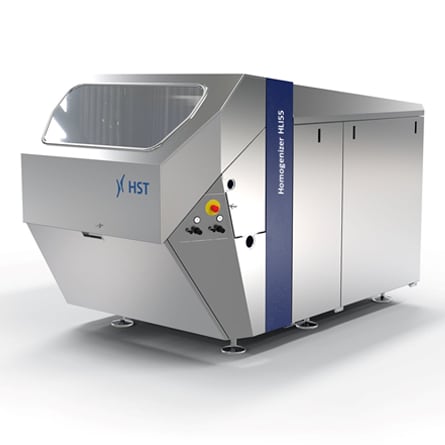

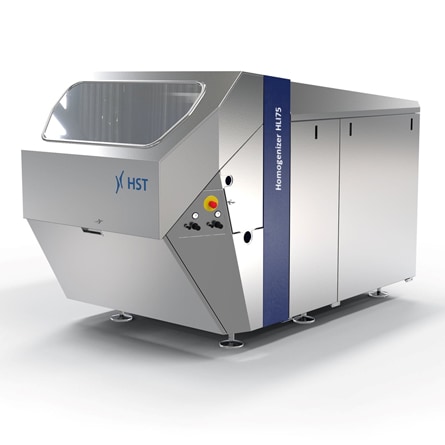

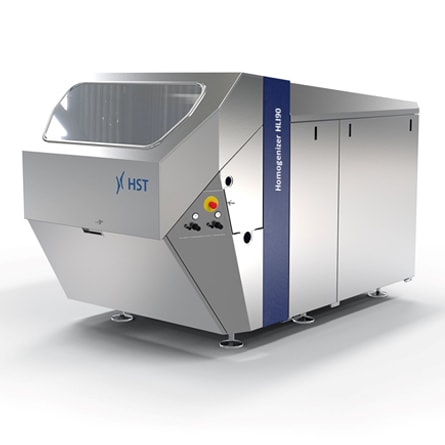

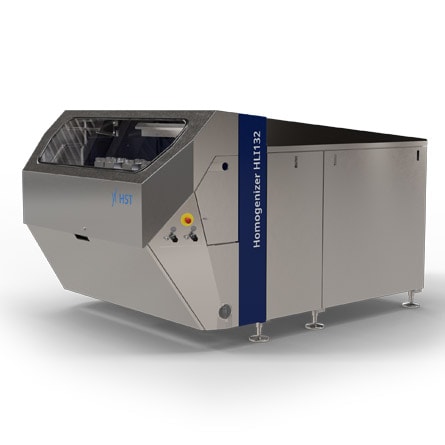

Series HLI 55 – 132 und HLI400

Integrated’ machine series with reduced water consumption. Performance ranges: 8,000 to 26,500 l/h, with HLI 400 to 63,000 l/h (at 150 bar)

- Maximal homogenization pressure: 700 bar

- Maximal 26,500 litres per hour (at 150 bar)

- Motor power: 55 – 132 kW

- Compact drive designed for 150 kW/200 hp, with a maximum power consumption of 132 kW

- Internal lubrication: no cooling water, no additional units, thus conserving resources

- Excellent cleaning results in the CIP process thanks to high-quality surface quality and avoidance of dead spaces, compliant with EHEDG and 3-A standards

- Pneumatic adjustment of the homogenization valve (<90 kW)

- Optionally available in aseptic design

- Soundproof housing

Versions and options

Product diversity requires variable technology

The product characteristics require a careful selection of suitable materials as well as associated designs. The components used by HST have been developed under practical conditions, tested many times and can be modified according to the application. We offer comprehensive advice on the configuration of your HST homogenizer, so that individually adapted to the needs of your product, an optimal homogenizing result is achieved.

Homogenizing valves

All valves offered by HST are highly efficient, low-noise and easy to service. Different valve materials such as high-strength stainless steels, sintered materials or ceramics can be used to achieve optimum homogenizing effects for a wide variety of products.

As homogenizing valves we offer PLUG, PILOTED and the energy-saving Multigap for our HST homogenizers. The valves are controlled pneumatically or hydraulically, depending on the flow rate and valve size.

Piston versions

The material of our pistons can be adapted exactly to your product properties. We offer standard pistons, chrome-plated pistons, ceramic pistons and pistons with a special HST coating. This HST special coating reduces the abrasion on the piston, which significantly extends the lifetime. In order to guarantee optimum running smoothness of the HST homogenizer, the piston geometry is individually designed on the basis of the given process parameters. This has a noticeable positive effect on the noise emission of the homogenizer, as well as a significant reduction of pulsation in your downstream process.

HST packing system

Tailored to the many different properties of your product, we offer a wide range of materials to enable maximum service life in conjunction with the appropriate piston design. The HST packing system guaranteed a significant extension of service life.

Aseptic design

The aseptic homogenization technique is often used for processing UHT or sterile products. The homogenization only takes place after heat treatment, which significantly increases the creaming stability. HST homogenizers are available in septic or aseptic design. By using on-site superheated steam, condensate or even sterile water as a barrier in aseptic HST homogenizers, recontamination of your product can be excluded.

Versatile in use

Wide range of applications

- Fresh milk

- Cream

- Vegetable juices

- UHT milk

- Yoghurt

- Baby and infant food

- Condensed milk

- Ketchup

- Sauces and dressings

- Mixed ice cream

- Fruit juices

- Egg products

- Special drinks

- Intravenous emulsions

- Liposomes

- Ingredients

- Textures

- Beauty creams

- Dyes

- Ointments

- Cell disruption

- Pigment dispersions

- Lubricants

- Fuels/water emulsions

- Wax emulsions

- Insecticides/herbicides

- Resin dispersions

- Nanosomes

- Colours

- Latex

- Uniform distribution of particles and liquids in pastes, slurries or suspensions

- Production of electrode slurries (anode and cathode)

- Production of electrolytes

- Coating compounds and slurry recycling

- Separator coating

Service-Hotline

Tel. +49 38826 887877

E-Mail

service@hst-gmbh.com